I’m interviewed on this week’s Get A Grip On Lighting podcast. You can listen, watch on YouTube, and more here.

I’m interviewed on this week’s Get A Grip On Lighting podcast. You can listen, watch on YouTube, and more here.

Earlier this month, CIE published CIE Position Statement on Color Quality Metrics, in which it recommends the lighting industry transition from the outdated and sometimes inaccurate General Color Rendering Index (CRI) to the General Color Fidelity Index (Rf ) defined in CIE 224:2017. The position statement notes that problems with CRI (which we’ve known about for years) include use of an outdated color space (CIE 1960 (u, v)), the small number of samples used to calculate CRI (only 8), and that CRI has proven to be especially problematic in evaluating narrow band emitters.

The good news is that CIE is finally recommending retiring CRI from use (which was last updated over 50 years ago in 1974) and adopting a modern, accurate metric for evaluating fidelity for all lighting applications. That’s a huge step forward for the lighting industry.

The less good news is that it stops there. The position statement acknowledges that fidelity is not the only aspect of color rendering, and that studies have shown preferences for light sources that slightly enhance saturation (and therefore reduce fidelity). However, it makes no mention of other metrics (such as ANSI/IES TM-30’s Gamut Index and Preference Design Intent) that address the issue. Since CIE 227’s Rf and TM-30’s Rf are identical, I see this as a belated endorsement of Rf as a fidelity metric and of TM-30 in general. My hope is that this spurs the industry to greater adoption of TM-30, especially for its evaluation of color preference, vividness, and fidelity described in Annex E.

One side note: Rf as defined in CIE 227 is Rf as defined in TM-30. In fact, TM-30 was published two years before CIE 227, which was a response to TM-30. In evaluating TM-30, CIE found that there were a few places where CIE and IES chose different methods of extrapolating certain information. Since CIE had formalized their procedures and IES had not, the two organizations worked together to harmonize their calculations into one calculation that is used in both systems. It’s frustrating that the CIE position statement reads as if CIE developed Rf out of whole cloth, rather than as a response to TM-30 and a mutual refinement of the Rf calculation.

If you look up the definition of Correlated Color Temperature (CCT) in IES LS-1 you’ll find, “The absolute temperature of a blackbody whose chromaticity most nearly resembles that of the light source.” It seems straightforward. The spectra of non-incandescent light sources don’t exactly match a blackbody radiator. They’ll plot off the blackbody locus in a chromaticity diagram. A CCT calculation identifies the color temperature closest to the light source in question – that’s the CCT. We all know that.

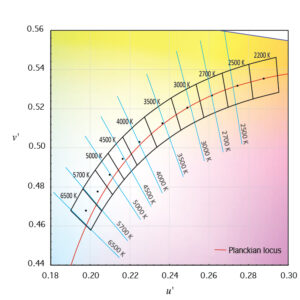

Not long ago someone on the IES Color Committee suggested that we develop and issue a standardized CCT calculation. My first thought was, “What? Are you saying that after decades of specifying CCT there’s no industry standard calculation method? What’s going on?” It turns out that since the late 1930s at least a dozen CCT calculation methods have been developed but none of them have been adopted by a standards setting body like the IES or CIE. The same is true for Duv, the direction and distance between the chromaticity coordinates of the light source and the nearest point on the blackbody locus. This means that the method used is up to the LED or equipment manufacturer, and can vary from one manufacturer to another.

Now, for lighting designers this isn’t a problem. Variations between the calculation methods generally aren’t large (although they can range from less than 1/1000th to several hundred K), and we are selecting LEDs described by their nominal CCT as outlined in NEMA C78.377, not their exact CCT. Those chromaticity quadrangles are huge, roughly 400 – 500 K wide and over 7 MacAdam ellipses, as shown below. For lighting designers the problem is the huge variation possible within a single CCT designation, but that’s for another day.

But, for LED manufacturers, testing equipment manufacturers, and researchers this can be a real problem. If two people attempt to precisely measure the same LED and arrive at two different CCTs how would they determine who’s right, or which calculation is “better”?

Now we have an answer. ANSI/IES TM-40 IES Method for Determining Correlated Color Temperature (CCT) and Distance from the Planckian Locus of Light Sources describes a CCT calculation method with an error of less than 0.1 K that calculates Duv based on the result of the CCT calculation. While there’s no way to compel anyone to use this method, it is an American National Standard developed under the ANSI process, making it the closest thing we have to an industry standard. Finally.

Here’s an interesting article about color perception, specifically blue/green perception, from The Guardian. There’s also a link to a fun web site where you can test your blue/green perception.

Source: Do you see blue or green? This viral test plays with color perception | Well actually | The Guardian

I’ll be giving a presentation on TM-30 (naturally) at the American Lighting Association Conference in Palm Beach, FL on September 23rd. If you’re at the conference and/or a fan of TM-30 stop by and say hi.

It’s been a while since I’ve posted anything because I’ve been working on a new book. More on that as we get closer to the publication date. Meanwhile, I’ve been asked (somewhat at the last minute) to speak on Monday June 3rd at an upcoming AIA New York event called Healing Light: The Biological and Social Effects of Lighting. The presentation will be an introduction to color temperature and color rendering and is primarily targeted at architects and interior designers who are new to lighting. Registration is free to AIA members and students, and only $10 for the general public.

I have written a lot about TM-30 from the specifier’s viewpoint – how TM-30 is better than CRI, explanations of the various TM-30 measures. why TM-30 data and reports are so important, how to get TM-30 data or reports, how to use TM-30, etc.

This month’s LD+A has a great article about TM-30 from the manufacturer’s viewpoint that addresses issues such as – why TM-30 reports for every LED option aren’t always available, why some manufacturers are reluctant to prepare TM-30 reports, strategies specifiers can use to deal with these issues, and more. It’s a very useful article. Give it a read at TM-30 Update: Challenges and strategies for working with SSL manufacturers – Illuminating Engineering Society %

Recently a colleague of mine from the IES Color Committee asked of one of the new AIs “Tell me about color rendering.” If we assume that the answer was formulated based on information about color rendering that is available on the internet we have a problem because the answer the AI returned was almost completely wrong. That strongly suggests that most individuals and manufacturers posting information about color rendering don’t fully understand color rendering and are perpetuating outdated or incorrect information. Here’s what the AI had to say, and what’s wrong with it’s response.

Color rendering is a measure of how well a light source reveals the true colors of objects. (1) A light source with a high CRI (Color Rendering Index) will show objects in their natural colors (2), while a light source with a low CRI will make objects look dull or washed out (3). The CRI is a scale from 0 to 100 (4), with 100 being the perfect score (5). A light source with a CRI of 100 will show objects in their true colors (1) while a light source with a CRI if 0 will make all objects look the same color (6).

The CRI (7) is important for applications where it is important to see objects in their true colors (1), such as art galleries, hospitals, and retail stores (8). It is also important for applications where it is important to see subtle variations in color such as fashion design and photography (9).

There are a few things that can affect the CRI of a light source (10). The type of light source (incandescent, fluorescent, LED, etc.) will affect the CRI (11). The color temperature of the light source will also affect the CRI (12). Light sources with a higher color temperature will have a higher CRI (12).

The CRI (7) is a valuable tool for choosing the right light source for your application. By understanding the CRI, you can choose a light source that will show your objects in their true colors (1) and help you achiever the desired look and feel for your space.

As part of the conversation around Diversity, Equity, Inclusion, and Respect there’s been a lot of discussion about color rendering and skin tone. I recently heard one speaker say something like, “We know that historical SPDs are racist.” I don’t think that’s accurate or helpful. Here’s why.

Since the development of the fluorescent lamp, the first priority for lamp manufacturers has been maximizing efficacy – getting the most lumens per watt. That’s still largely true today, even though LEDs are so efficient that there’s a lot of room for other considerations. An exclusive focus on efficacy inevitably results in poor color rendering, so the second priority has been acceptable (not maximized) color rendering. In other words, manufacturers have tried to find the right balance between efficacy and quality, but they emphasize efficacy.

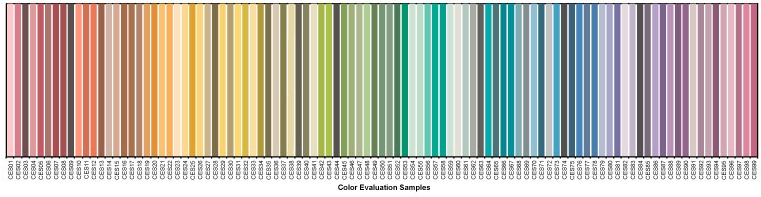

When evaluating color rendering, manufacturers only look at the numbers. Whether it’s a calculation of CRI, Rf, Rg, or something else, it’s all done mathematically. There’s no interest in comparing the calculated values with empirical observations. The eight colors used to calculate CRI are a limited range that don’t include a representation of skin, as shown below.

The 99 colors used for TM-30 calculations span the color space and are not weighted toward any hue, tint, or value, as shown below.

So, there’s never been a focus on caucasian skin tone to the detriment of others because skin tone isn’t part of the evaluation.

Does that mean that all skin tones are rendered equitably? Honestly, we don’t know. On one hand, there’s no reason to think that we evaluate skin tone differently than we evaluate other surfaces. It’s reasonable to expect that a high fidelity source, for example, that give cars, apples, and kittens a good color appearance will do the same for human skin.

On the other hand, we don’t have good studies to confirm that. It may be that we hold different criteria for evaluating skin than we do for apples, resulting in the need for a separate skin tone rendering metric. Again, today we just don’t know.

In fact, the IES Color Committee is looking at this right now. We’ve started with an effort to gather as many studies as we can find – though there are very few that focus on skin rendering. The next step is to evaluate the literature to determine if additional study is needed, and what such a study (or studies) would require and evaluate. The hard part is funding the studies, and that would be the next step. Eventually, we’d have some solid science from high quality studies that would tell us if skin tone is evaluated differently than other surfaces, and if so what the calculation of a skin tone metric should include. The goal is to use the appropriate TM-30 measures (remember, there are 149 of them) to evaluate skin tone rendering, and to add a skin tone metric (maybe Rs) to TM-30, if needed.

If you’re interested in joining the task group looking at this, please contact me.