In this article from the IEEE the inventor of Li-Fi explains how it works.

In this article from the IEEE the inventor of Li-Fi explains how it works.

As the co-chair of the IES Color Committee I am delighted (pun intended) to announce the publication of the Design Guide for Color and Illumination. The guide is the result of over five years of work by more than a dozen researchers, engineers, manufacturers, and designers from across the globe. Here’s part of the description on the IES site.

Color can be described using concrete values such as chromaticity coordinates, spectral power distribution, or others discussed later in this guide. However, one’s response to color can be much more personal and emotional—and therefore more difficult to quantify. This guide takes the reader from basic vision and color vocabulary, through methods of measuring and quantifying color, and culminates in the practical use of commercially available white light and colored lights. The definitions, metrics, and references discussed will assist in building a critical understanding of the use and application of color in lighting.

It is probably the best, most thorough discussion of light and color available today. Everyone interested in color, color perception, color rendering, and their relationship to light should read it. It will be available at the IES booth at Lightfair.

News stories generated by the American Medical Association’s (AMA) community guidance on street lighting has elevated the topic of LED street lighting and its potential effects on health and the environment in the public’s mind. Discussions of these issues have many misperceptions and mischaracterizations of the technical information, and the difference between what has and hasn’t been scientifically established is often blurred.

DOE has assembled a variety of resources on the topic, to provide accurate, in-depth information that clarifies the current state of scientific understanding.

Source: Street Lighting and Blue Light | Department of Energy

In September the DOE issued, Energy Savings Forecast of Solid-State Lighting in General Illumination Applications (PDF, 116 pages), the latest edition of a biannual report which models the adoption of LEDs in the U.S. general-lighting market, along with associated energy savings, based on the full potential DOE has determined to be technically feasible over time. The new report projects that energy savings from LED lighting will top 5 quadrillion Btus (quads) annually by 2035. Among the key findings:

Don’t have time for the full report? Download the report summary.

I’m putting the finishing touches on a lighting design and as I look at cut sheets I continue to be disappointed that many fixture manufacturers still don’t seem to understand the proper methods of measuring and reporting LED life. For example, an Edison Price cut sheet says that lamp life is “rated 50,000 hours based on L70/B50 criteria. LM80 report by the LED manufacturer furnished upon request,” a USAI cut sheet says that life is “Based on IESNA LM80-2008 50,000 hours at 70% lumen maintenance (L70),” and a Lighting Services Inc. cut sheet just says “Tested to LM79 and LM80 Protocols” and then gives a life of 50,000 hours. Unfortunately, these statements don’t mean what the manufacturers suggest they mean. Let’s take a look.

Back in the early days of LEDs of lighting (say around 2005!) it was the wild west in terms of manufacturers reporting product life. The rated life of traditional lamps is the amount of time that passes until one-half of a sample set has burned out. LEDs don’t burn out, they just get dimmer and dimmer over time, so many LED manufacturers estimated the amount of time until an LED’s output had fallen to one-half and called that the LED’s life. This led to reported lifetimes of over 100,000 hours, which sounds great until you realize that at 100,000 hours the space you’re lighting is only half as bright as it was at the first hour. How many of our designs provide twice as much light on day one so that we can lose 50% of the light and still provide an acceptable light level? None! Clearly the industry needed another method of calculating life.

Somehow (sorry, I don’t know the history of this) the industry settled on a loss of 30% of output as the lifetime of an LED. This is in line with the Lamp Lumen Depreciation (LLD) factor applied to many CFL and HID lamps in illuminance calculations. The lifetime to 70% of initial light output is often abbreviated as L70. Many lighting designers have pointed out that a 30% loss of light is pretty poor performance and some manufacturers have responded by providing L80, and even L90, data (that is, the life until the LED has lost 10% of its initial brightness). All of this was a step in the right direction, but there was no standard method for taking the measurements to determine L70.

In 2008 the Illuminating Engineering Society stepped up to clarify things with LM-80-08 Approved Method: Measuring Lumen Maintenance of LED Light Sources. LM-80 (LM stands for Lumen Maintenance) specifies the test conditions and methods to be used to measure and report the lumen maintenance of an LED package. Data is collected every 1,000 hours for a minimum of 6,000 hours. Even accurately collected LM-80 data isn’t ideal, though. LM-80 is used to evaluate LED packages, not entire fixtures, so the conditions of the test (temperature, electrical characteristics of the driver, etc.) may, or may not, be similar to those in the assembled and installed fixture.

Importantly, LM-80 does not provide a method of extrapolating the 6,000 hours of data to predict future performance. As a result, any cut sheet saying that a 50,000 hour life is calculated according to LM-80 is misstating things unless the manufacturer has actually had the same LED packages under test. 50,000 hours translates to nearly six years, to that’s unlikely. LM-80 was revised in 2015 and is now the ANSI standard ANSI/IES LM-80-15 IES Approved Method: Measuring Luminous Flux and Color Maintenance of LED Packages, Arrays and Modules.

How do manufacturers calculate an LED’s life? They (should) use IES TM-21-11 Projecting Long Term Lumen Maintenance of LED Light Sources. TM-21 (TM stands for Technical Memorandum) describes a method for projecting the lumen maintenance of LEDs using the data collected during LM-80 testing. So, a cut sheet should say something like, “L70 life of 50,000 hours based on LM-80 testing data according to TM-21 protocol.”

The statements I quoted at the beginning leave wiggle room for the manufacturers to provide lifetimes that may, or may not, be calculated according to TM-21. TM-21 is the only standard we have that allows us to compare apples to apples, so omitting a statement about using TM-21 as the basis of lifetime calculation should make you suspicious about the reported life. It’s also important to understand that LM-80 is a testing procedure, and TM-21 is a calculation procedure. They are not tests. There’s no such thing as an LED that “passes” LM-80 or TM-21 (as some reps have tried to tell me). LM-80 and TM-21 produce information about the life of an LED that the designer uses to assess the appropriateness of a fixture.

Specifiers need to tell reps and manufacturers that LED life must be calculated according to TM-21. It’s the only way to be sure that the lifetimes of various fixtures are all calculated the same way so that we can make reasonable comparisons. They should also urge the IES to develop a procedure that tests a complete fixture: housing, power supply, and LEDs. That’s going to be the best estimate of the true life of an LED fixture. Yes it will take time, but we need accurate information that is calculated the same way across all manufacturers.

A former student of mine who works for Edison Price Lighting is organizing a group of seminars they’re calling “Light In Action.” It takes place here in NYC at EPL’s showroom and factory, and includes demonstrations of lighting techniques, discussions on the future of LEDs (led by a representative from Xicato) and dimming LEDs (led by a representative from eldoLED), as well as a factory tour. Sounds fun, right? There are six dates between now and the end of the year. Visit EPL’s web site for more information.

In another example of LEDs growing dominance in the lighting industry, General Electric has announced that it is “breaking up” with CFL lamps, and that it will stop manufacturing and sales of spiral retrofit lamps in the U.S. by the end of this year. According GE, CFLs and LEDs each accounted for about 15 percent of lamps sales last year. The sales of LEDs are increasing and sales of CFLs are decreasing.

A few weeks ago I gave a three-hour seminar on lighting museums and galleries to the graduate students in an art curating program at a university here in New York. Condensing everything I’d like to say into less than three hours was tough. The two big questions were what to include and what to leave out. I started with a quick overview of how to think about light and lighting before moving on to basic vocabulary and some common lighting techniques. Then, since LEDs are clearly the future, even when lighting art, I moved on to an overview of both color temperature and color rendering. I talked about reference materials such as the IES Lighting Handbook, intensity and brightness ratios, and other considerations before we moved into their gallery space to use their track light system for some demonstrations.

After the whole affair a faculty member, who sat in on most of the seminar, said he had hoped I would have spent much more time talking about how to use track lights and less time on unimportant issues like design, color temperature, and color rendering (!). I was respectful, but stunned. Focusing track lights is so complex that it requires extensive demonstrations? Understanding that with LEDs the color qualities of the light vary widely, and can only be properly selected when they are understood is unimportant information? Uhh…NO. Or, as my 20 month old niece says, “no no no no.”

Yes, five or ten years ago the default light source in museums was an incandescent or halogen lamp. The color temperature difference was minor and the color rendering of both was excellent. That’s not true today. Look at the cut sheet for any museum grade track light and you’ll see that you have a choice of several color temperatures and CRI values. If ANYONE needs to understand the qualities of light that must be selected when using LED fixtures, if anyone needs to understand the affect that color temperature and CRI have on how colors are perceived, it’s certainly people involved in displaying and lighting art. To me, that means the curators of exhibits and the lighting designers they hire.

As I’ve discussed earlier, changing the color temperature of the light changes the color appearance of objects, as shown below.

The phenomenon of color consistency means that the shift in color appearance isn’t as great as one might expect or as these photos suggest, but the shifts are real. If you’ve ever bought a black garment only to discover later that it was actually dark blue you’ve experienced this shift. A similar thing happens when we compare a high CRI light source and a low CRI light source. If your work involves color perception this is basic and critical information.

Curators can be forgiven for not knowing much about this, but if they know nothing how can they collaborate with their lighting designer to show the art as they intend? Administrators and curators of museums and galleries – educate yourselves, then hire a lighting designer!

I’ve been hired to review an architect’s lighting design and then design an appropriate control system. The fixtures selected are all LED products by a manufacturer that falls into the high-end residential/economy commercial range of quality and price. The cut sheets are extremely frustrating. After nearly a decade of LED lighting, and with all of the progress the industry has made in setting standards so that designers and specifiers know what they’re getting, this manufacturer still tells us nothing. What basic information is missing?

Lamp life. The only information even remotely connected to lamp life is the statement that the fixture is covered under a five-year warranty. There’s nothing else. Not a word. How much light, compared to initial output, can we expect at that five-year mark? We have no idea.

LEDs do not fail like other lamps do. They gradually dim as they age. At what point is the light output so low that we’d say the lamp is no longer useful? Right now the answer is when the light output has fallen to 70% of the initial output (often referred to as L70), although many designers prefer to use 80% of initial output (referred to as L80). This is calculated using a procedure developed by the IES and designated as LM-80 (details are here and here). What we want, at a minimum, is the IES LM-80 calculation of lamp life to 70% of initial output. L80 data would be even better.

Warranty. The warranty is not on the manufacturer’s web site so, although we’re told that it is good for five years, we have no information about what is covered and what is excluded.

LED manufacturer. With all other lamp types the designer chooses the exact lamp for the project. Criteria such as initial lumen output, mean lumen output, lamp life, color temperature, CRI, and the manufacturer’s reputation for quality are all valid considerations. We have standards that allow designers to make valid comparisons between LED products, too, but we can do that only if that information is generated and shared. I suspect that this fixture manufacturer uses LEDs from a several manufacturers based on the best price available, and that the performance of those LEDs varies widely.

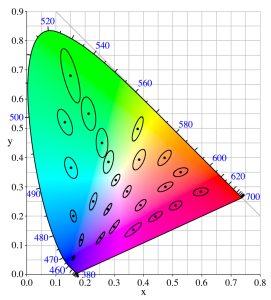

Color consistency. The cut sheet says that the standard applied to their LED selection is, “minimum 3-step color binning.” We are left to infer that means three-step MacAdam Ellipses. A one-step MacAdam Ellipse describes a region on a chromaticity diagram or color space where the edges of the ellipse represent a just noticeable difference from the color at the center (additional information on MacAdam Ellipses is here and here). The data is usually plotted on the CIE 1931 (x, y) chromaticity diagram. The diagram below shows 10-step MacAdam Ellipses.

The color variation within a three-step ellipse would be noticeable to over 99% of the population. Worse, though, is that a three-step ellipse is the minimum, not the maximum. Knowing this, the designer should have no expectation of color consistency from one fixture to another.

Photometrics. The cut sheet contains no information about the optical performance of the fixture. IES files are available, but it’s very difficult to look at the array of numbers and understand performance, which is why the good manufacturers include photometric information on their documentation, including candlepower distribution curves and CU tables.

Part of my review will be pointing out the lack of data about the specified fixtures and recommending several alternates by manufacturers who provide the information necessary to evaluate their products.

A recent article in The Wall Street Journal discussed the possibilities and benefits of lighting systems that shift color to mimic the changes in daylight. It’s a complicated subject so it’s not surprising that some of what’s reported is inaccurate, so let me clarify a few things.

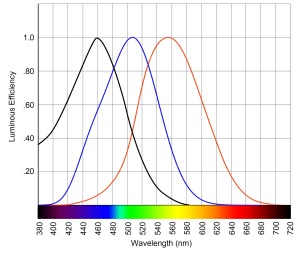

First, our current understanding of how light affects our circadian rhythms is that a light activates a type of cell in the retina called intrinsically photosensitive retinal ganglion cells (ipRGC). These cells, unlike rods and cones, are unrelated to vision. The signal they send to the brain is received by the suprachiasmatic nucleus (SCN), which is the body’s hormone regulator. As the graph below illustrates, the ipRGCs are most sensitive to short wavelength (blue) light and, unlike rods and cones, are unaffected by long wavelength (red) light. (A more detailed explanation can be found in Chapter 16 of Designing With Light, and in this article from the Journal of Circadian Rhythms.)

The ipRGCs signal to the SCN, which keeps our circadian rhythms are kept in sync with the day/night cycle, seems to be affected by three factors: color balance; intensity; timing. Cool (bluish) light should be delivered at a relatively high brightness in the morning hours. Delivering cool light in the evening hours can disrupt sleep and other processes controlled by the SCN.

Next, there’s nothing special about LED lighting that makes it uniquely appropriate for this application. Fluorescent, HID, and incandescent light (adjusted with color filters) can all be used to create a system that delivers cool light in the morning and warm light in the evening. In all cases, this involves the use of light sources of several tints (warm, cool, and possibly neutral) that are individually controlled. The WSJ is completely wrong when it says “unlike incandescent or fluorescent lights, LED lights’ materials and electronic components allow for finer adjustments of color, brightness and intensity.” A single LED creates light of a single color. To shift colors a second LED is required. Brightness and intensity are the same thing. With LEDs set to surpass sales of all other light sources within the next several years, research involving sources other than LED is nearly non-existent. Naturally, researchers are using LEDs to test theories and to develop demonstrations and products.

Finally, it would be helpful if the WSJ had defined two terms – color temperature and CRI (Color Rendering Index). Both are explained in Chapter 8. Color rendering and CRI are briefly explained in this post. CRI and color temperature are both addressed in this post.