Recently a designer specified 0-10V dimming for a series of LED downlights. The electrician powered the LEDs by connecting them to a nearby breaker panel. The 0-10V control signal was generated by the lighting control system. This was a simple system that should have worked with no problems. Much to everyone’s surprise the lights would dim but they wouldn’t go off! What happened?

Dimming light sources other than incandescent is a technical challenge. It requires the ballast (for fluorescent, HID, cold cathode, etc.) or the driver (for LEDs) to precisely control the amperage and the voltage, and may also require converting the incoming AC to a DC output (for some LEDs). This is difficult for fluorescent and HID lamps because the electricity must arc from one side of the lamp to the other, and at low power levels that arc simply fails. Dimming LEDs often results in a visibly jittery dimming curve as well as a jump to zero when dimming down and a jump to on when dimming up. (This article in Electrical Construction & Maintenance is a good overview of the problems with dimming LEDs.)

In architectural lighting, however, the inability to dim all the way to zero is usually not seen as a problem. Typical dimming applications such as classrooms and meeting rooms may want to dim lights for a presentation, but some light is still desirable so that attendees can see each other for discussion and see their desktop to take notes. Dimming is acceptable as long as the dimming is smooth down to a minimum light level. In these installations the drop from, say, ten percent to zero isn’t an issue because it doesn’t happen until the room is empty and the lights are turned completely off.

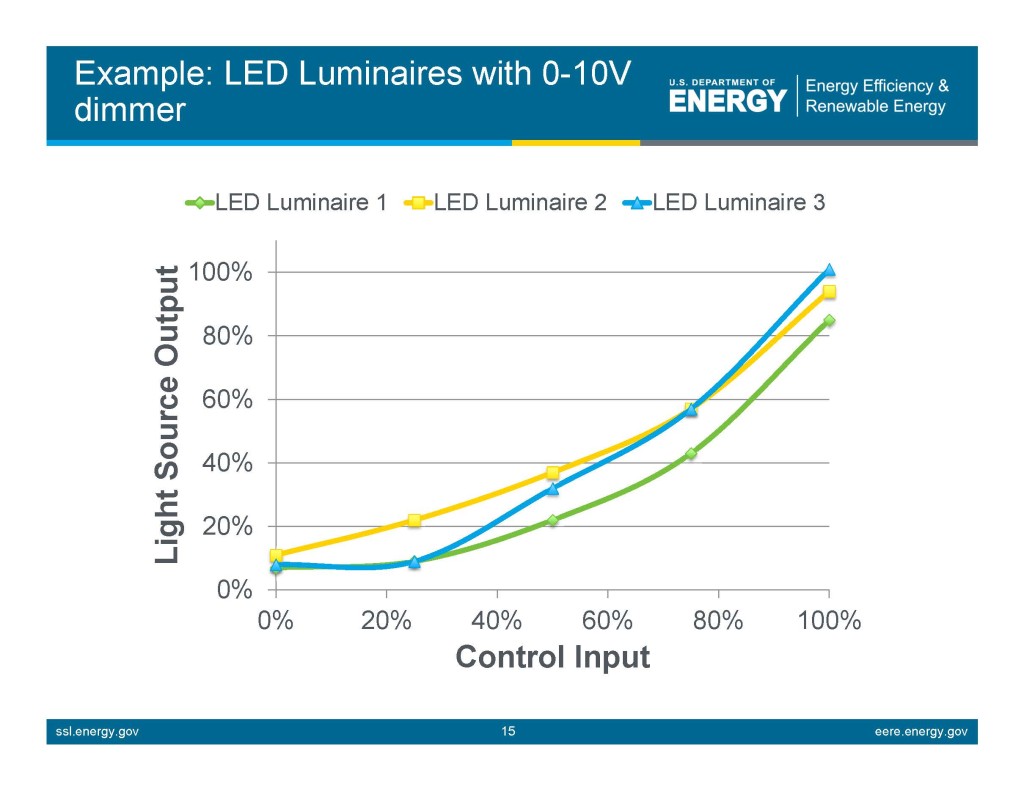

With 0-10V dimming, though, the dimmer or driver is powered by the incoming line voltage, so its always operating. As a result, its minimum operating capacity is also the fully dimmed state. A 100-10% ballast or driver, for example, has a minimum output of 10% not zero. When the fader is at the bottom of its travel we would normally expect the lights to go off, but they only go to 10%. Here’s a graph showing the performance of representative LED fixtures dimmed with a 0-10V dimmer.

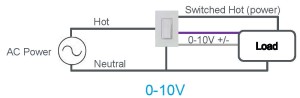

The solution is to provide separate switching of the line voltage delivered to the fixture. Most wallbox dimmers have a toggle switch below the fader so that the fixture can be shut off at any time. Here’s a schematic of a simple circuit.

Other solutions come from other dimming techniques, including three-wire and four-wire dimming where the line voltage and the control signal come out of the same device. This guarantees that at a minimum state power to the fixture is shut off. Other control protocols, notably DMX512, and the electronics that utilize them can usually dim to zero.