I’m putting the finishing touches on a lighting design and as I look at cut sheets I continue to be disappointed that many fixture manufacturers still don’t seem to understand the proper methods of measuring and reporting LED life. For example, an Edison Price cut sheet says that lamp life is “rated 50,000 hours based on L70/B50 criteria. LM80 report by the LED manufacturer furnished upon request,” a USAI cut sheet says that life is “Based on IESNA LM80-2008 50,000 hours at 70% lumen maintenance (L70),” and a Lighting Services Inc. cut sheet just says “Tested to LM79 and LM80 Protocols” and then gives a life of 50,000 hours. Unfortunately, these statements don’t mean what the manufacturers suggest they mean. Let’s take a look.

Back in the early days of LEDs of lighting (say around 2005!) it was the wild west in terms of manufacturers reporting product life. The rated life of traditional lamps is the amount of time that passes until one-half of a sample set has burned out. LEDs don’t burn out, they just get dimmer and dimmer over time, so many LED manufacturers estimated the amount of time until an LED’s output had fallen to one-half and called that the LED’s life. This led to reported lifetimes of over 100,000 hours, which sounds great until you realize that at 100,000 hours the space you’re lighting is only half as bright as it was at the first hour. How many of our designs provide twice as much light on day one so that we can lose 50% of the light and still provide an acceptable light level? None! Clearly the industry needed another method of calculating life.

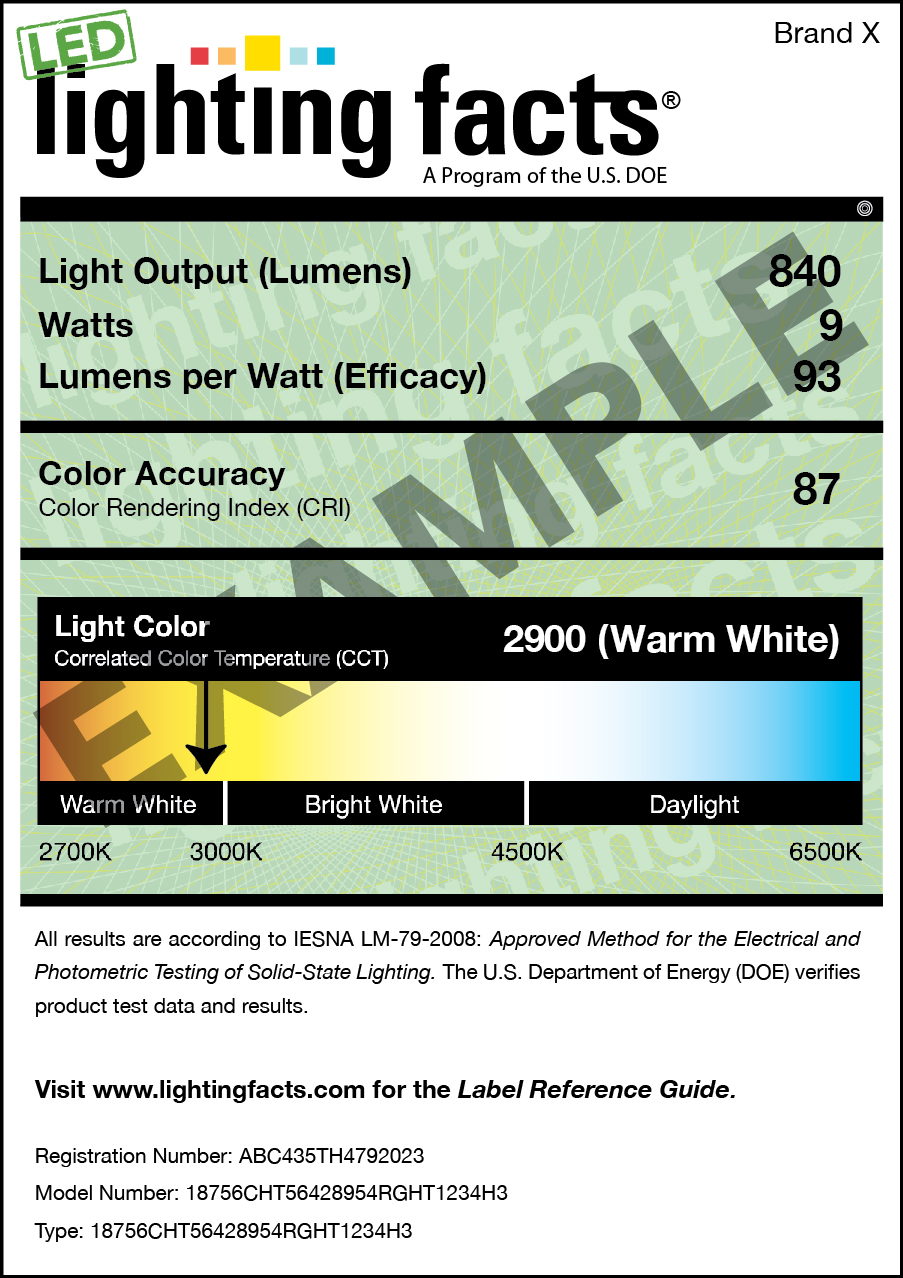

Somehow (sorry, I don’t know the history of this) the industry settled on a loss of 30% of output as the lifetime of an LED. This is in line with the Lamp Lumen Depreciation (LLD) factor applied to many CFL and HID lamps in illuminance calculations. The lifetime to 70% of initial light output is often abbreviated as L70. Many lighting designers have pointed out that a 30% loss of light is pretty poor performance and some manufacturers have responded by providing L80, and even L90, data (that is, the life until the LED has lost 10% of its initial brightness). All of this was a step in the right direction, but there was no standard method for taking the measurements to determine L70.

In 2008 the Illuminating Engineering Society stepped up to clarify things with LM-80-08 Approved Method: Measuring Lumen Maintenance of LED Light Sources. LM-80 (LM stands for Lumen Maintenance) specifies the test conditions and methods to be used to measure and report the lumen maintenance of an LED package. Data is collected every 1,000 hours for a minimum of 6,000 hours. Even accurately collected LM-80 data isn’t ideal, though. LM-80 is used to evaluate LED packages, not entire fixtures, so the conditions of the test (temperature, electrical characteristics of the driver, etc.) may, or may not, be similar to those in the assembled and installed fixture.

Importantly, LM-80 does not provide a method of extrapolating the 6,000 hours of data to predict future performance. As a result, any cut sheet saying that a 50,000 hour life is calculated according to LM-80 is misstating things unless the manufacturer has actually had the same LED packages under test. 50,000 hours translates to nearly six years, to that’s unlikely. LM-80 was revised in 2015 and is now the ANSI standard ANSI/IES LM-80-15 IES Approved Method: Measuring Luminous Flux and Color Maintenance of LED Packages, Arrays and Modules.

How do manufacturers calculate an LED’s life? They (should) use IES TM-21-11 Projecting Long Term Lumen Maintenance of LED Light Sources. TM-21 (TM stands for Technical Memorandum) describes a method for projecting the lumen maintenance of LEDs using the data collected during LM-80 testing. So, a cut sheet should say something like, “L70 life of 50,000 hours based on LM-80 testing data according to TM-21 protocol.”

The statements I quoted at the beginning leave wiggle room for the manufacturers to provide lifetimes that may, or may not, be calculated according to TM-21. TM-21 is the only standard we have that allows us to compare apples to apples, so omitting a statement about using TM-21 as the basis of lifetime calculation should make you suspicious about the reported life. It’s also important to understand that LM-80 is a testing procedure, and TM-21 is a calculation procedure. They are not tests. There’s no such thing as an LED that “passes” LM-80 or TM-21 (as some reps have tried to tell me). LM-80 and TM-21 produce information about the life of an LED that the designer uses to assess the appropriateness of a fixture.

Specifiers need to tell reps and manufacturers that LED life must be calculated according to TM-21. It’s the only way to be sure that the lifetimes of various fixtures are all calculated the same way so that we can make reasonable comparisons. They should also urge the IES to develop a procedure that tests a complete fixture: housing, power supply, and LEDs. That’s going to be the best estimate of the true life of an LED fixture. Yes it will take time, but we need accurate information that is calculated the same way across all manufacturers.