It’s been a little over two years since the IES released TM-30-15 IES Method for Evaluating Light Source Color Rendition. In that time TM-30 has seen growing support in the industry and a growing body of evidence for its accuracy and usefulness. We’ve nearly reached the moment when we can all agree that it’s time to retire CRI and fully adopt a modern, accurate system of measuring and describing the color rendering of light sources. What’s wrong with CRI? Quite a bit, so if you’re not up to date on the issue here’s an overview.

In 1948 The CIE first recommended a color rendering index based on a method developed in 1937. The 1937 method is a fidelity metric (that is, it compares a test light source to a reference light source) that divides the spectrum into eight bands and compares each band to a full spectrum radiator. In 1965 the CIE finally adopted CIE 13-1965 Recommended method of measuring and specifying color rendering properties of light sources, based on a test color sample method, what today we call CRI Ra or just CRI. From the start it was apparent that there were problems. In 1967 a committee was established to correct for adaptive color shift. Other problems were uncovered, and in 1974 a formal update was published. Errors were uncovered in the 1974 edition, resulting in a third version in 1994, which is the version we use today.

So far, so good. Errors are discovered in the method used and are eventually corrected, so what’s the fuss? The fuss is that the corrections were minor compared to the scope of the errors, and 23 years after the last correction we still don’t have an accurate, up to date system. In the early 1990s a proposal to update the formula and test color samples failed to gain consensus. Two subsequent attempts to improve the metric also closed without adoption. The current problems, as described in the 2011 IES Lighting Handbook, 10th Edition include:

- Averaging the color shifts of the eight test colors says nothing about the rendering of any single sample. A large error in one color can be masked by accurate rendering of the other samples.

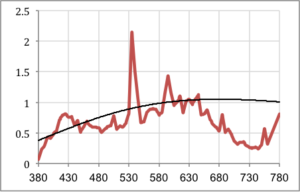

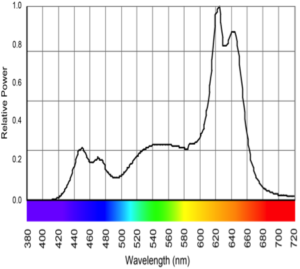

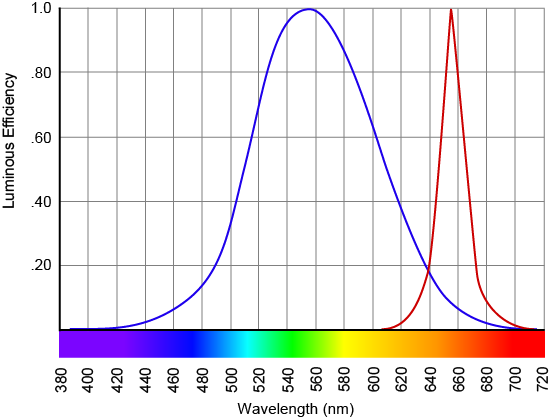

- The test color samples are all of moderate saturation so the index doesn’t reveal color shifts in saturated colors. In addition, the test colors are not evenly distributed through the color space or the spectrum, so light source spectra can be engineered to score higher than visual observation would indicate.

- The color space used, the 1964 UCS chromaticity diagram, is no longer recommended for any other use.

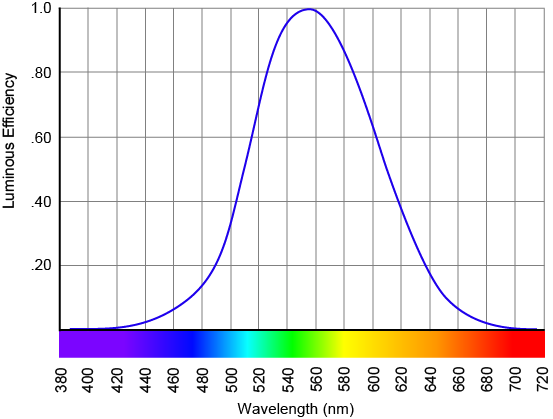

- All chroma shifts are penalized, even though research shows that moderately increasing chroma is desirable in many applications.

- The chromatic adaptation used has been shown to perform poorly and is no longer recommended for any other use.

- A single number index gives no information about the direction or extent of color shift for any particular color or color range.

Why haven’t these problems been corrected in the past 23 years? I’m told that there are two issues. The small issue is that competing scientific interests on the committee advocate new metrics that they’ve developed as a replacement or supplement to CRI. The larger problem is that manufacturers on the committee don’t want to see any changes that would reduce the CRI of any of their lamps. From their perspective, it’s better to have a high score on an inaccurate test than a low score on an accurate one. It seems that internal politics has been preventing updates, corrections, and improvements.

Although many other color rendering metrics have been proposed over the years, none has been adopted by CIE, which has the most significant voice on this issue. The result is that the sole internationally accepted metric, which has also been written into product specifications and into codes, is CRI. That began to change in 2015 with the introduction of TM-30. I’ll have more to say about TM-30 in future posts, but for now let’s agree that CRI Ra is broken and CIE is in no hurry to fix it. A better system exists, and our industry should adopt it.